Apron assembly repair is a vital process for maintaining vehicle integrity and safety, involving the specialized repair or replacement of lower body panels (aprons) that protect crucial components from impact and corrosion. This involves assessment, using correct techniques like welding or adhesives, and ensuring seamless integration with existing parts. Environmental safety compliance, guided by EPA guidelines, is crucial to protect workers and the environment from hazardous materials. Sustainability plays a key role through efficient repairs, minimizing waste, and adopting innovative eco-friendly techniques, contributing to global sustainability goals.

In the realm of industrial maintenance, efficient apron assembly repair is paramount for operational continuity. This article serves as a comprehensive guide, delving into the intricate processes and best practices surrounding apron assembly repair. We explore environmental safety compliance, highlighting critical regulations and sustainable strategies essential for today’s forward-thinking manufacturers. By understanding the interconnection between repair techniques and ecological stewardship, facilities can optimize their operations while minimizing environmental impact.

- Understanding Apron Assembly Repair: A Comprehensive Guide

- Environmental Safety Compliance: Regulations and Best Practices

- The Interconnection Between Repair and Sustainability

Understanding Apron Assembly Repair: A Comprehensive Guide

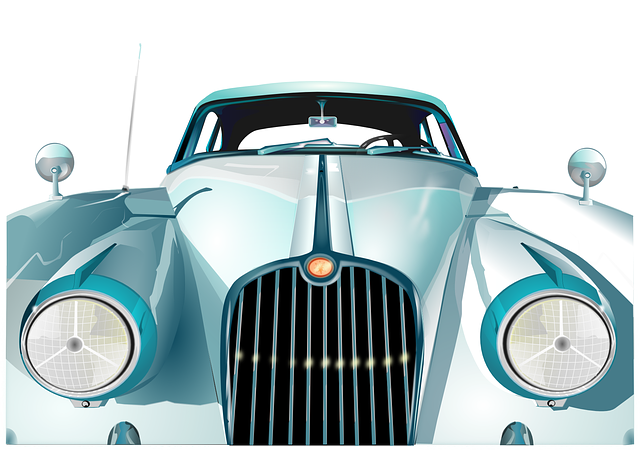

Apron assembly repair is a specialized process that involves fixing or replacing damaged components within the apron assembly of a vehicle. The apron, also known as the lower body panel, plays a crucial role in protecting the vehicle’s underbody and engine compartment from impact and corrosion. Over time, these parts can sustain wear and tear, leading to cracks, holes, or deformations that compromise structural integrity and aesthetic appeal.

Understanding apron assembly repair is essential for both professional mechanics and car owners. The process typically entails assessing the extent of damage, using appropriate tools and techniques to replace faulty parts, and ensuring seamless integration with existing vehicle components. This includes patching, welding, or using specialized adhesives to reinforce weaknesses. Regular maintenance and timely repairs are vital not only for optimal vehicle performance but also for adhering to environmental safety compliance standards, as proper apron assembly repair minimizes the risk of leaks and emissions from damaged auto bodywork, such as bumper repair and vehicle bodywork repairs.

Environmental Safety Compliance: Regulations and Best Practices

Environmental Safety Compliance is a vital aspect of any apron assembly repair operation. Regulations, such as those set by the Environmental Protection Agency (EPA), govern the disposal and treatment of hazardous materials commonly used in vehicle body repairs, including auto painting and auto dent repair. These regulations are designed to protect both workers and the surrounding environment from exposure to toxic chemicals. Best practices include implementing proper ventilation systems, using eco-friendly cleaning products, and ensuring all waste is disposed of in accordance with local, state, and federal guidelines.

Apron assembly repair facilities must adopt a proactive approach to environmental safety compliance. This involves regular training for staff on the latest regulations and best practices, as well as investment in up-to-date equipment that facilitates safer working conditions. By adhering to these standards, auto body repair shops not only avoid legal penalties but also contribute to a cleaner, healthier environment, fostering a positive reputation among customers who are increasingly conscious of sustainability issues.

The Interconnection Between Repair and Sustainability

In the realm of apron assembly repair, the interconnection with sustainability is profound. As businesses focus on fixing and revamping aprons for various industries, such as automotive and body shop services, eco-friendly practices become integral to the process. Efficient and precise repairs not only extend the lifespan of aprons but also significantly reduce waste, a key aspect in environmental safety compliance. By minimizing scrap materials generated during repair procedures, companies contribute to a greener environment, aligning with global sustainability goals.

Moreover, apron assembly repair encompasses more than just fixing physical components; it involves adopting innovative techniques and technologies that promote sustainability. For instance, the implementation of advanced bonding agents and reinforced fabrics can enhance apron durability, thereby reducing the need for frequent replacements. This not only saves resources but also minimizes the carbon footprint associated with auto body services and car dent repair processes. Thus, a holistic approach to apron assembly repair is essential in achieving both functional excellence and environmental stewardship.

Apron assembly repair is not just a technical process; it’s a critical component of environmental safety compliance. By understanding the intricate details of apron assembly and implementing best practices, industries can significantly reduce their ecological footprint. The interconnection between these aspects fosters sustainability, ensuring a safer and more secure working environment while preserving our planet’s resources for future generations.